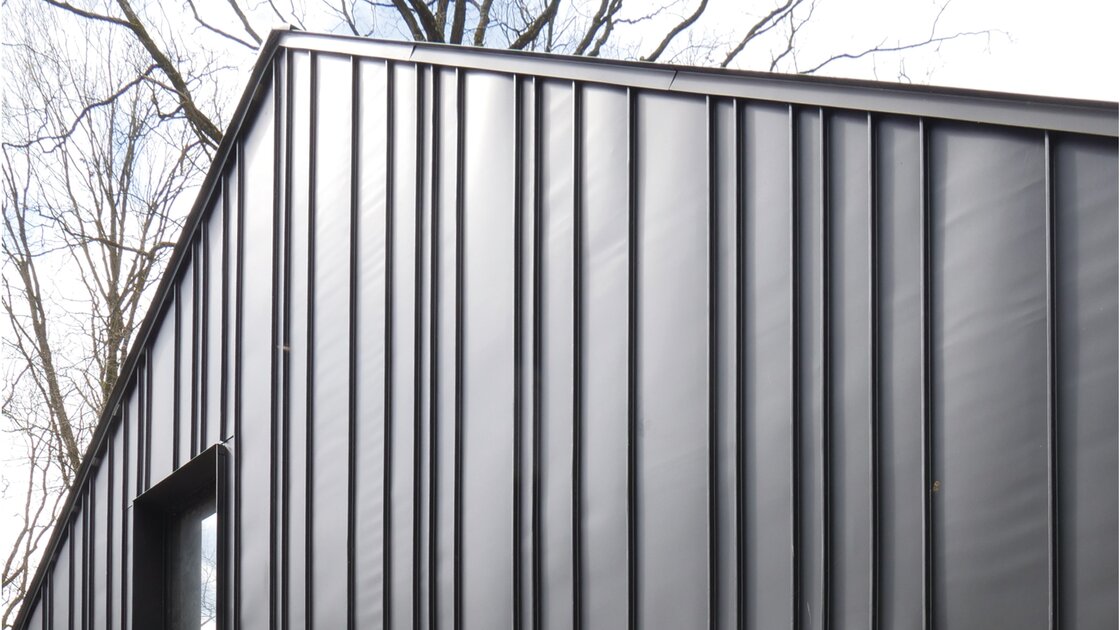

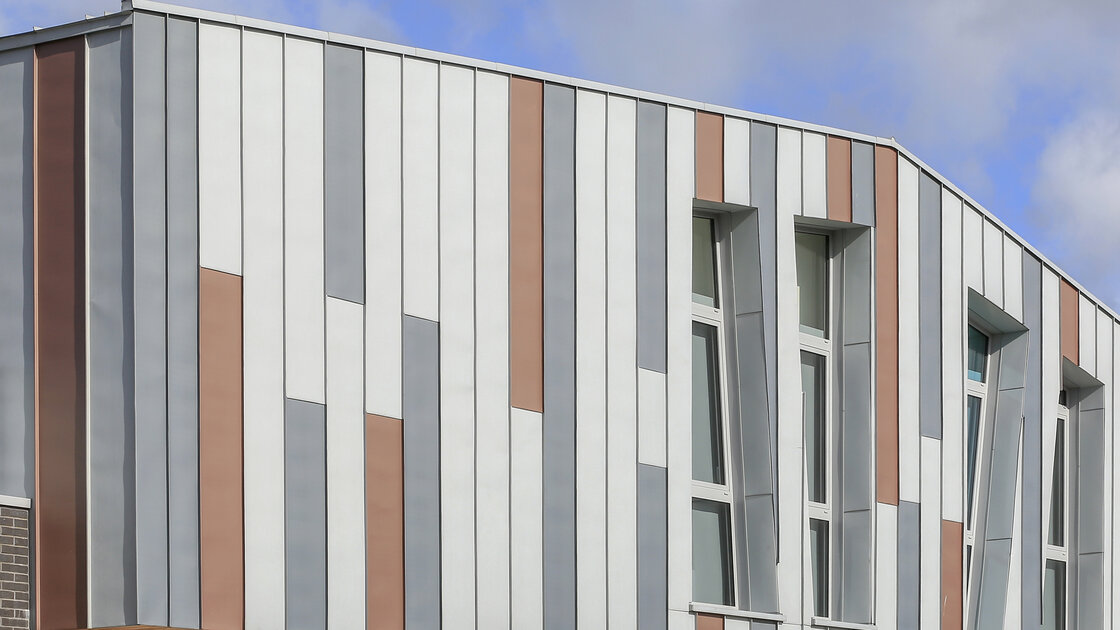

Single Lock Standing seam for facade

- Facade

- Clips

- Hidden

- Standing

- Standing seam

- Flexibility and discreet joints making it suitable for every architectural design

- Horizontal or vertical installation

General information

Standing seam is a single folded or double folded seam. The use of profiling and seaming machines for the closure of longitudinal seam joints significantly reduces installation time. The low height of the seams (25mm) contributes to the modernity, lightness and regularity of the roof and facade, while highlighting its architectural purpose.

When dealing with more complex designs this system presents a more technologically advanced appearance. The Standing seam technique is particularly suitable for very large roof and facade surfaces and for structures located in regions of harsh climate, which are often subject to strong winds, heavy rain and snowfall (mountain or continental climate).

Technical data

| Thickness | 0.8mm |

| Max Panel length | 4m |

| Panel width 430 mm | 430mm |

Finishes

See all aspects-

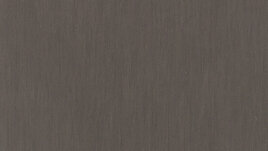

ANTHRA-ZINC

ANTHRA-ZINC -

AZENGAR

AZENGAR -

PIGMENTO Blue

PIGMENTO Blue -

PIGMENTO Brown

PIGMENTO Brown -

PIGMENTO Red

PIGMENTO Red -

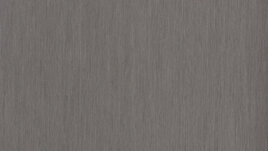

QUARTZ-ZINC

QUARTZ-ZINC -

Natural zinc

Natural zinc

Installation

See all our installation videosDescription

The panels are installed in a sequential order from either left to right or right to left for vertical panels. Horizontal panels must be installed from bottom up. For panels less than 2m in length fixed clips can be used. For longer panels sliding clips must be used towards the bottom on vertical panels and to the left and right of the centre for horizontal panels. When using single lock all clips can be fixed. VMZINC clips are made from 304 stainless steel and each clip must resist a pull-out force of 50daN.

It is recommended that screws be used to secure the clips with three being used per sliding clip. The use of nails offers significantly less resistance, but in the event of using nails, contractors are advised to use ring shank nails. The panels should be installed with the protective film in place.